以下是:黑龍江省304stainlesssteelchainplate質保一年的產品參數

| 產品參數 |

|---|

| 產品價格 | 1300/米 |

|---|

| 發貨期限 | 10 |

|---|

| 供貨總量 | 8574 |

|---|

| 運費說明 | 電議 |

|---|

| 小起訂 | 5 |

|---|

| 質量等級 | 優 |

|---|

| 是否廠家 | 是 |

|---|

| 產品材質 | 不銹鋼 碳鋼 |

|---|

| 產品品牌 | 魯寧 |

|---|

| 產品規格 | 定制 |

|---|

| 發貨城市 | 德州寧津 |

|---|

| 產品產地 | 浩宇機械 |

|---|

| 加工定制 | 加工定制 |

|---|

| 產品型號 | 客戶自定 |

|---|

| 可售賣地 | 全國 |

|---|

| 產品重量 | 根據實際參數定 |

|---|

| 質保時間 | 1年 |

|---|

| 外形尺寸 | 根據客戶定制 |

|---|

| 適用領域 | 食品加工,貨物輸送、噸包輸送 |

|---|

| 是否進口 | 否 |

|---|

| 產品功率 | 根據實際符合 |

|---|

| 工作溫度 | -30——40 |

|---|

| 范圍 | 304stainlesssteelchainplate生產基地位于【德州】,供應范圍覆蓋黑龍江省 哈爾濱市、齊齊哈爾市、鶴崗市、大慶市、佳木斯市、牡丹江市、黑河市、綏化市、大興安嶺市等區域。 |

|---|

【浩宇】為客戶提供多樣化產品,包括哈爾濱機、齊齊哈爾輸送帶、鶴崗機廠家、大興安嶺輸送機等,適配多元場景需求。304stainlesssteelchainplate質保一年,浩宇輸送機械制造廠(黑龍江省分公司)nxshu3109-6專業從事304stainlesssteelchainplate質保一年,聯系人:許經理,發貨地:經濟開發區泰山路南首路西,以下是304stainlesssteelchainplate質保一年的詳細頁面。 黑龍江省 黑龍江地貌特征為“五山一水一草三分田”。地勢大致呈西北、北部和東南部高,東北、西南部低,由山地、臺地、平原和水面構成;地跨黑龍江、烏蘇里江、松花江、綏芬河四大水系,屬溫帶季風氣候。黑龍江省位于東北亞區域腹地,是亞洲與太平洋地區陸路通往俄羅斯和歐洲大陸的重要通道,中國沿邊開放的重要窗口。黑龍江歷史代表文化為“東北文化”。

想要更直觀地了解304stainlesssteelchainplate質保一年產品的特點和功能嗎?我們為您準備了視頻介紹,相較于圖文,視頻更能讓您輕松掌握產品的核心賣點。

以下是:黑龍江304stainlesssteelchainplate質保一年的圖文介紹

浩宇輸送機械制造廠(黑龍江省分公司),地址:經濟開發區泰山路南首路西。 公司專業經營(黑龍江) 本地 機。歡迎新老客戶來我公司洽談。 我們以“優良的品質、優惠的價格、優質的服務”贏得了新老客戶的信賴和支持,在業界樹立起良好的信譽和口碑。 在此,公司經理攜全體員工,將憑借良好的信譽,雄厚的實力,優質的產品,低廉的價格服務于廣大用戶.謹向對公司一貫給予關懷、支持和幫助的新老朋友和廣大客戶表示衷心的感謝!并真誠希望與之建立長期的合作關系,互惠互利,共求發展。

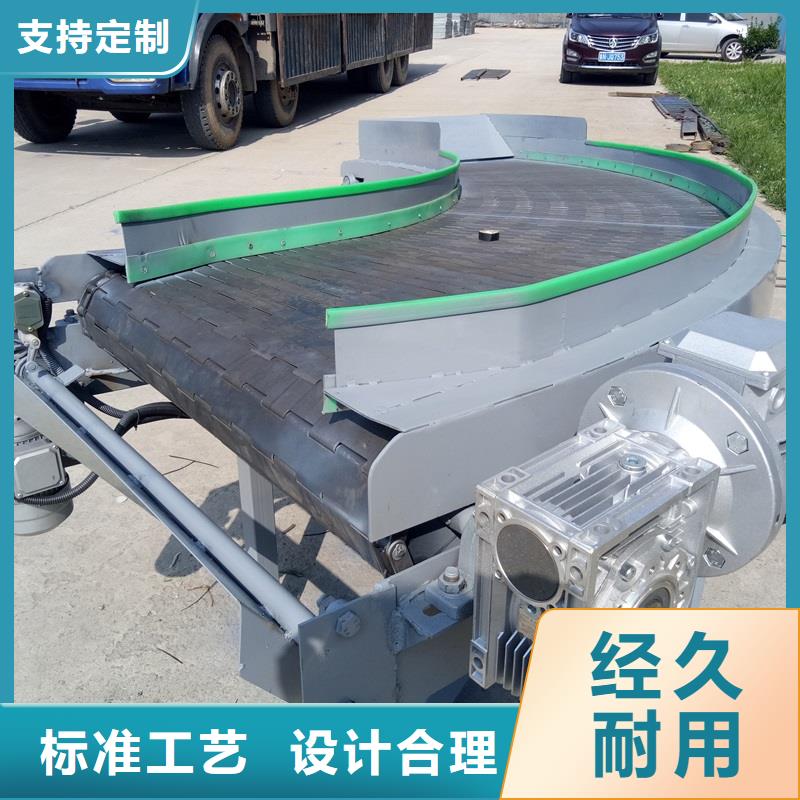

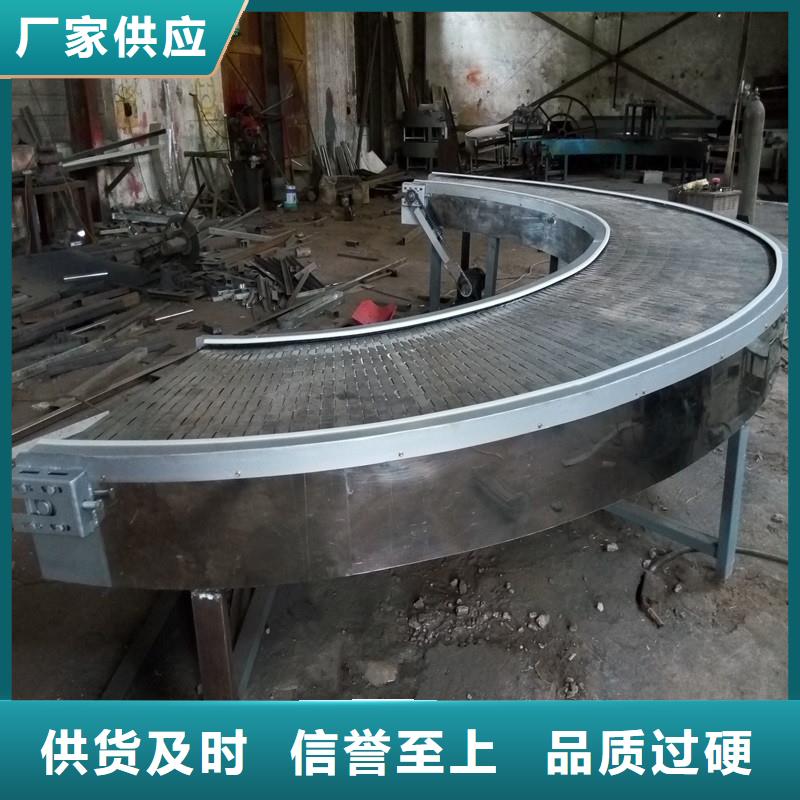

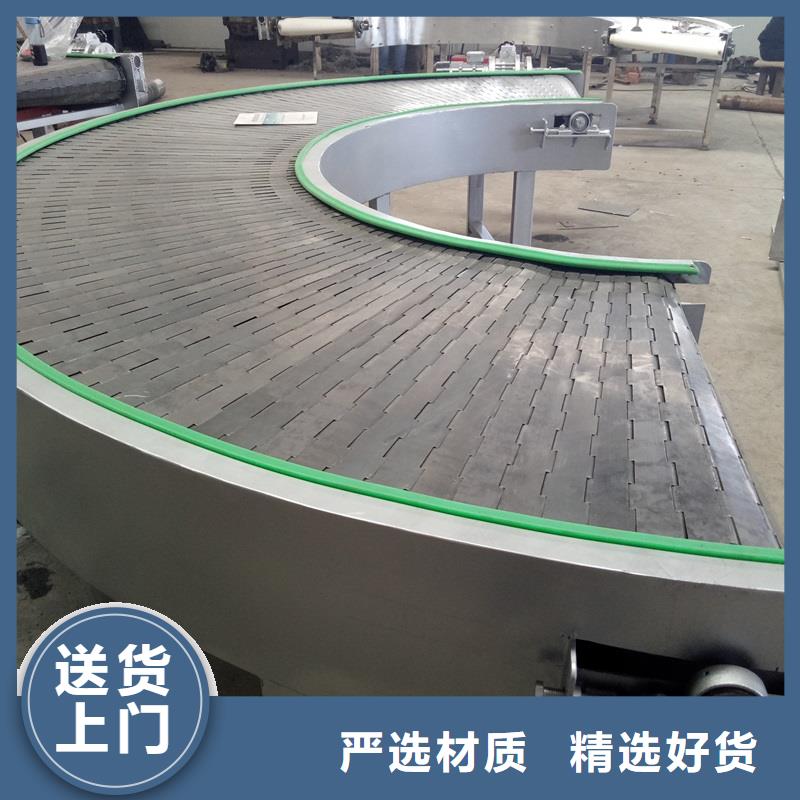

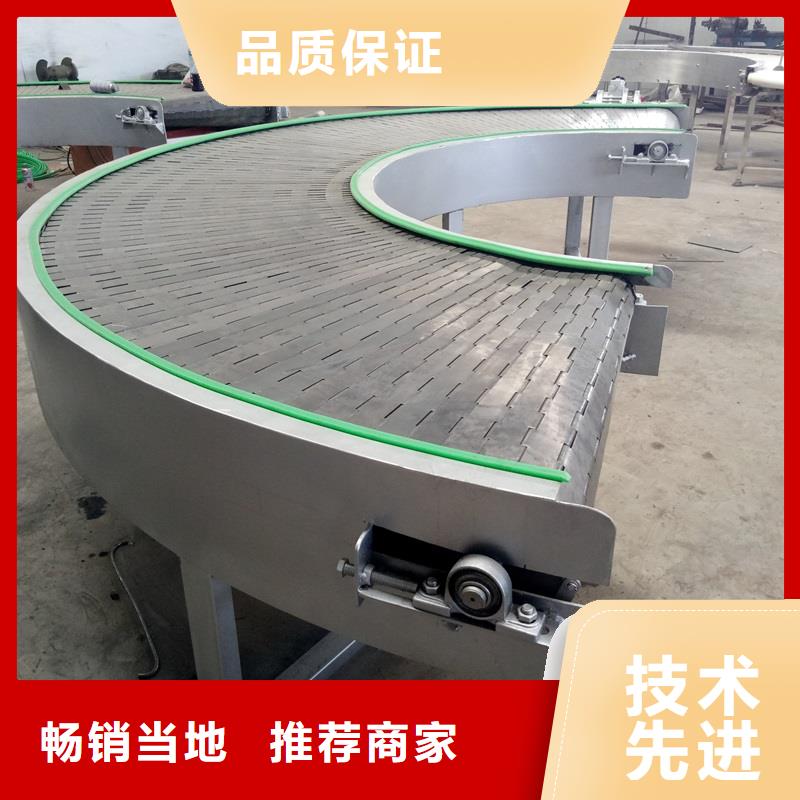

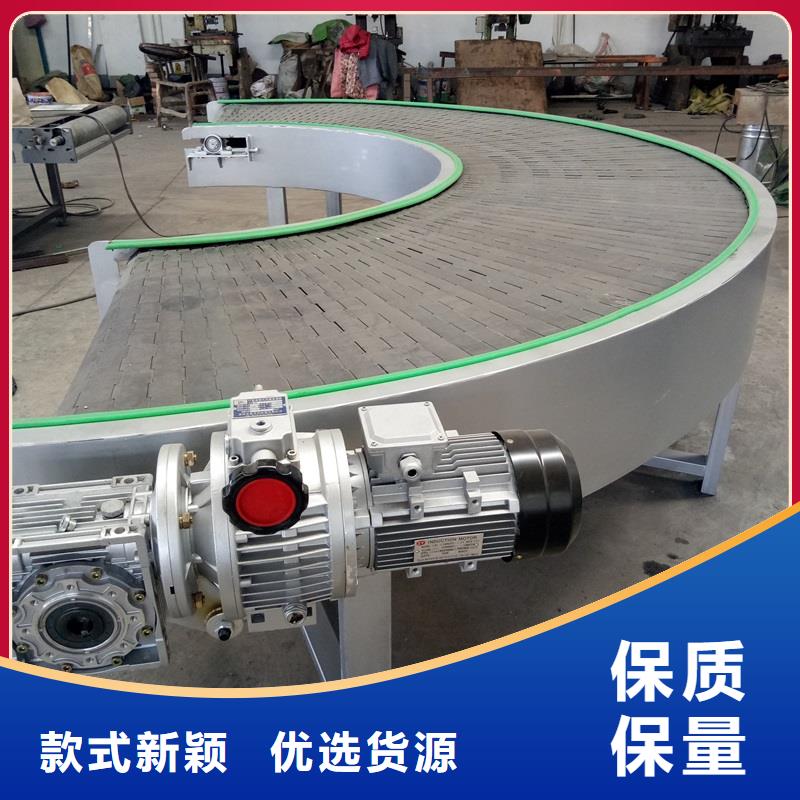

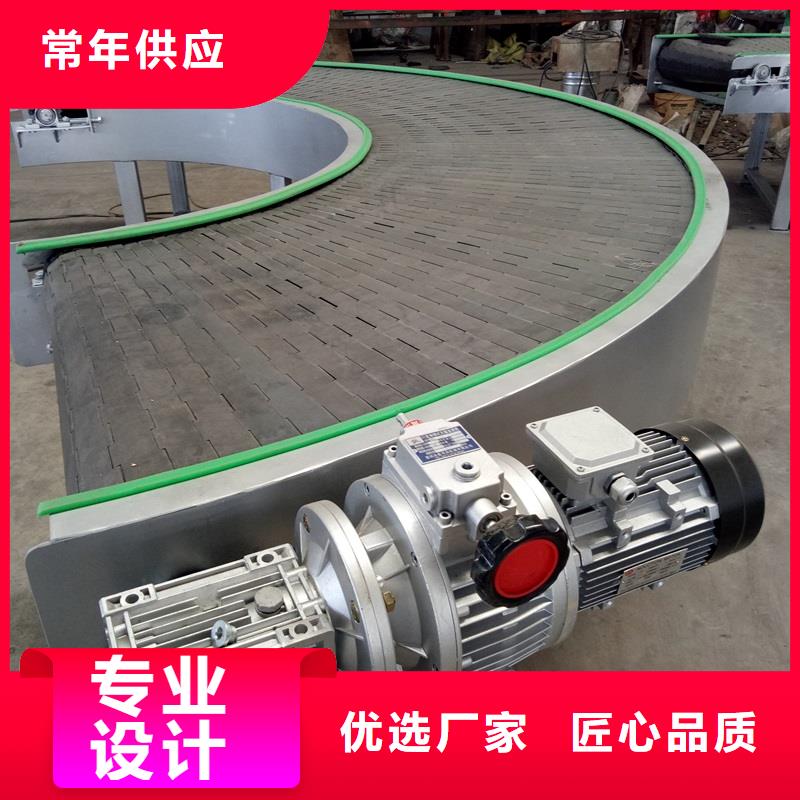

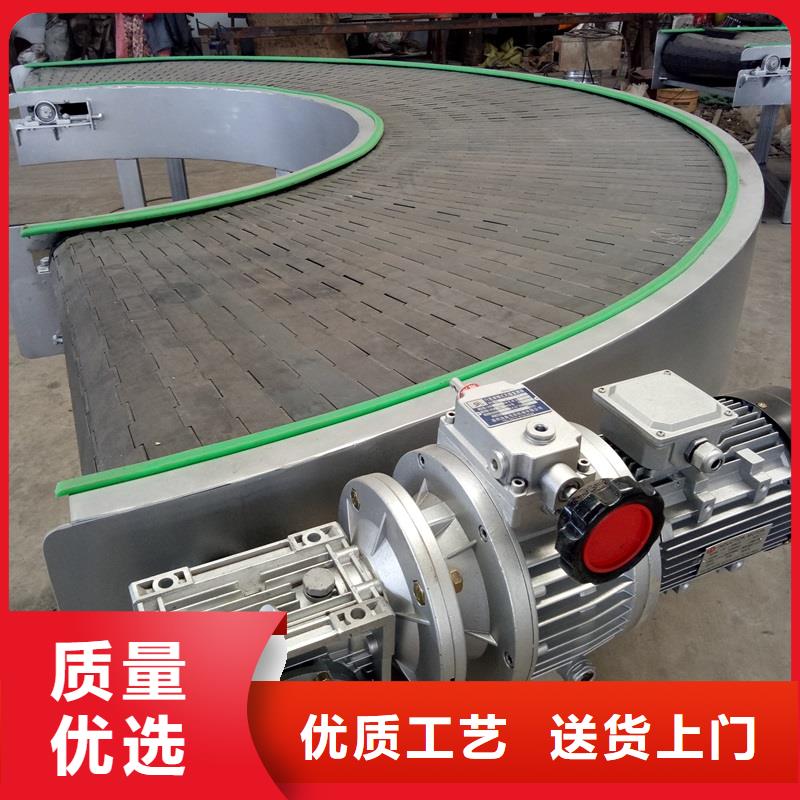

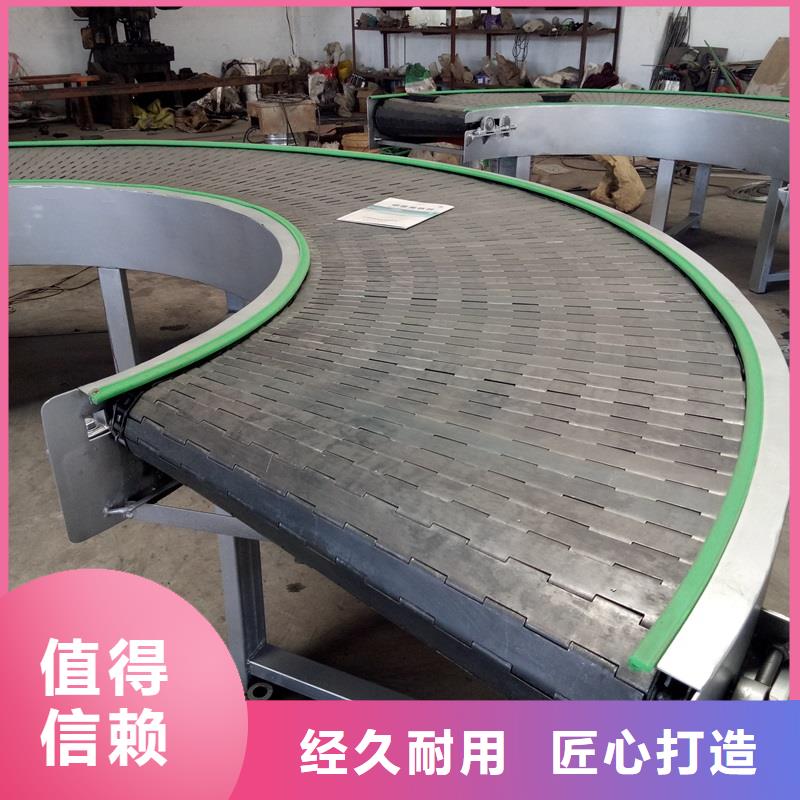

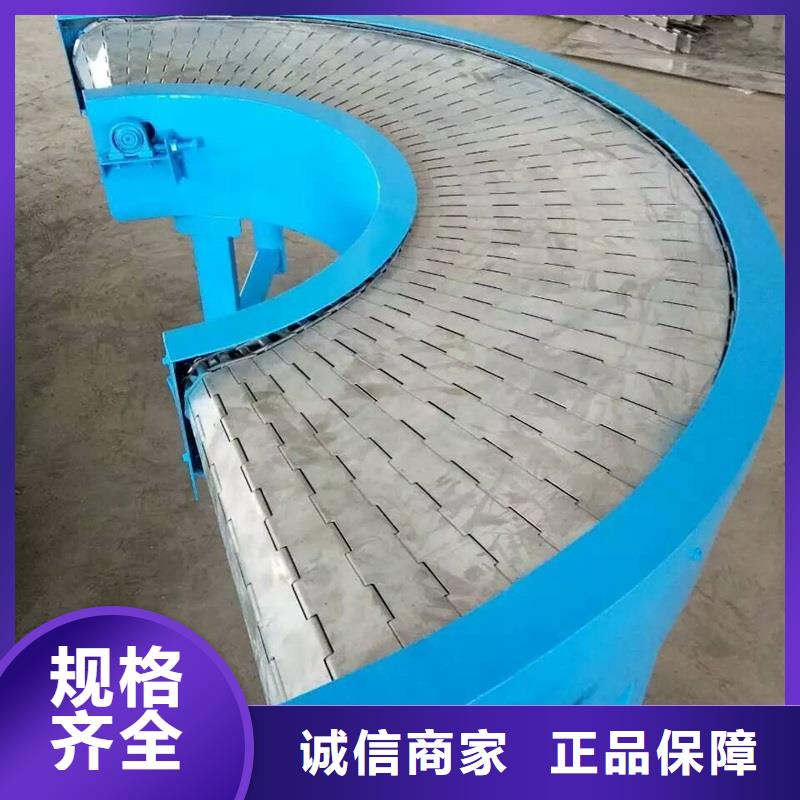

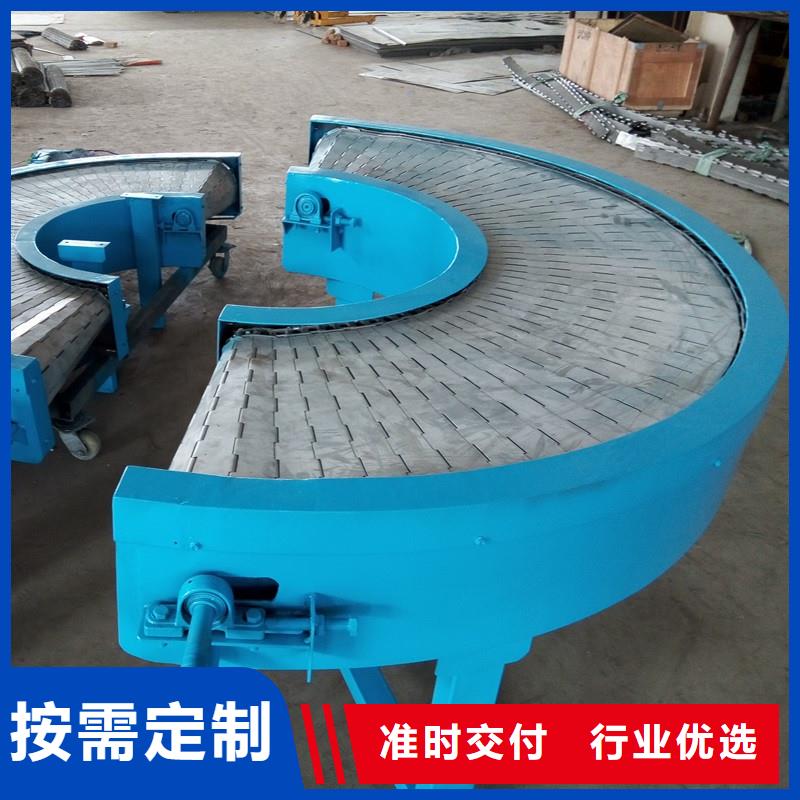

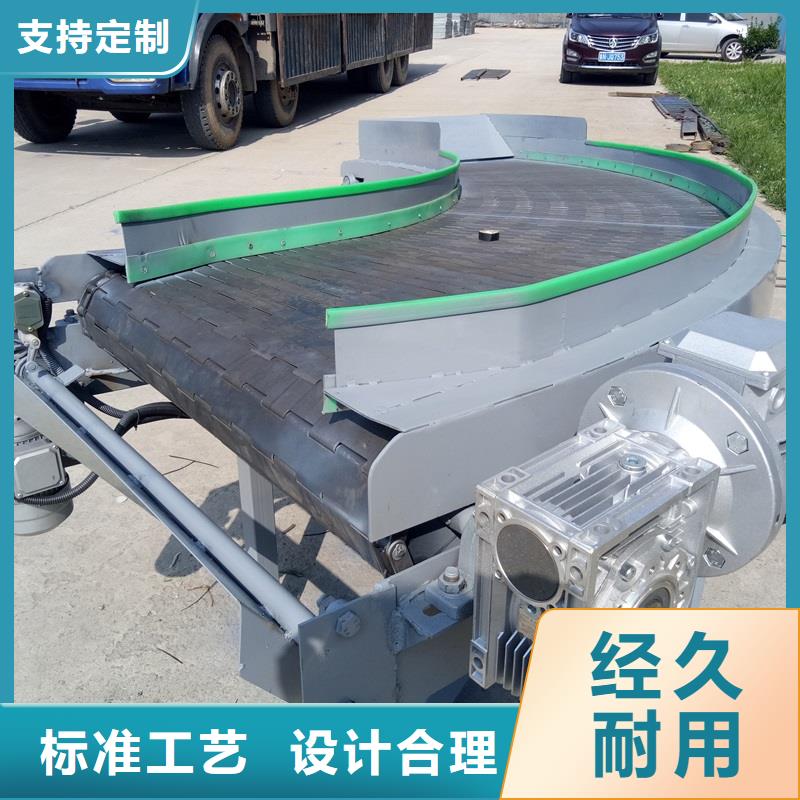

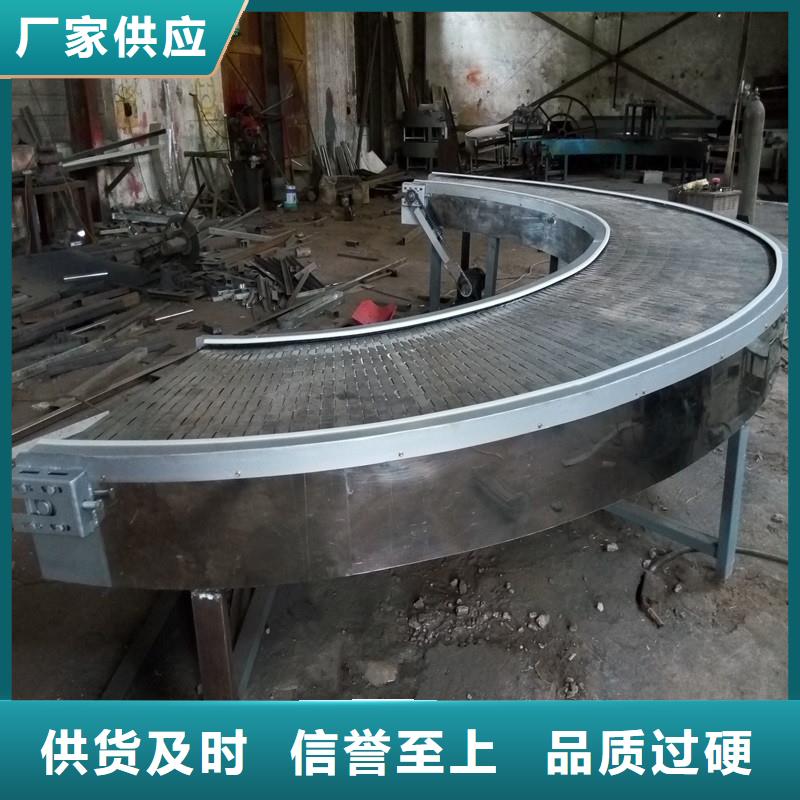

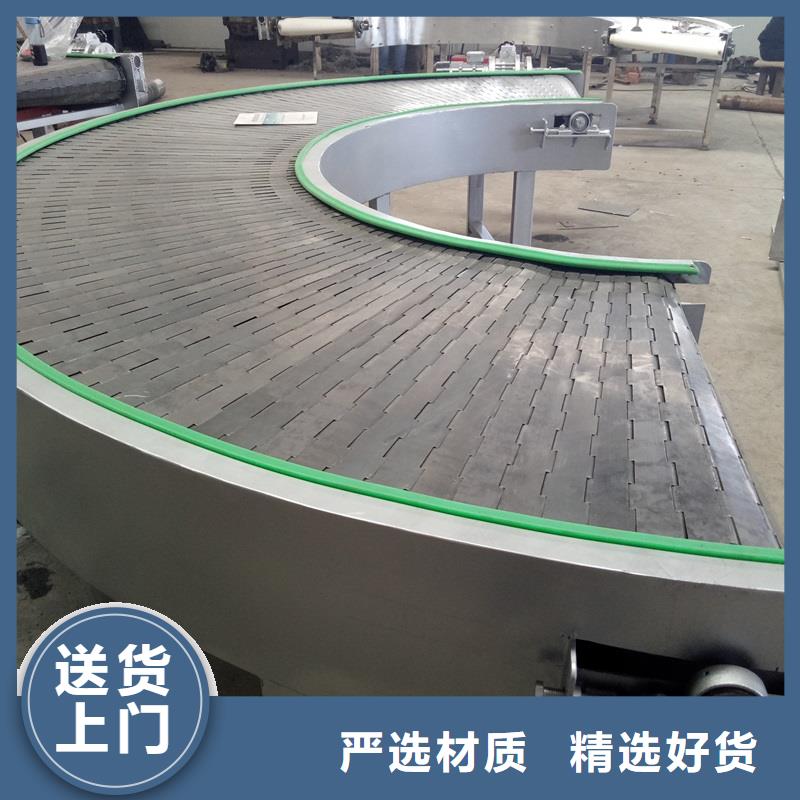

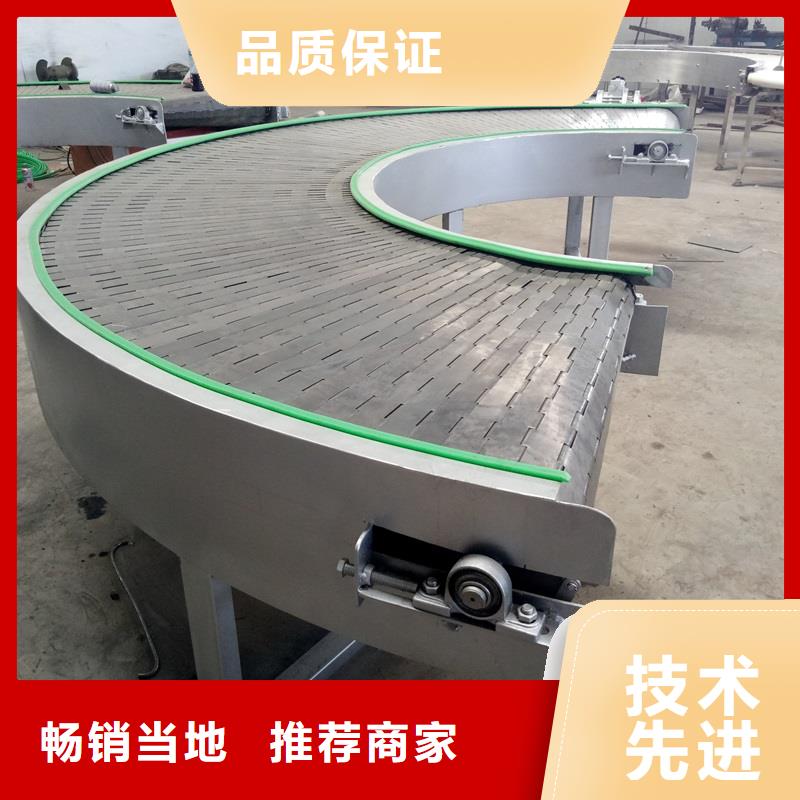

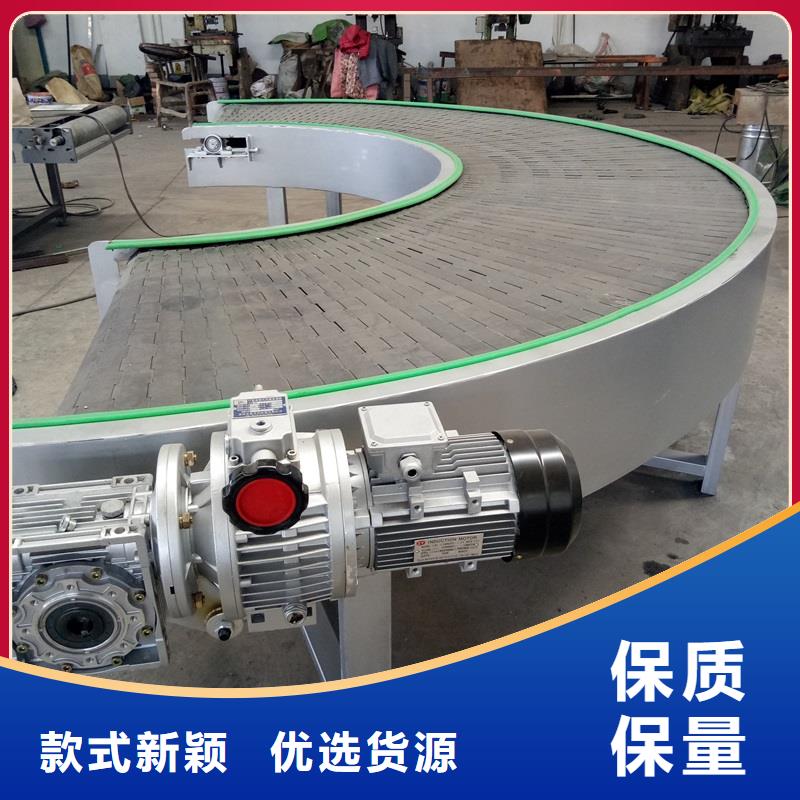

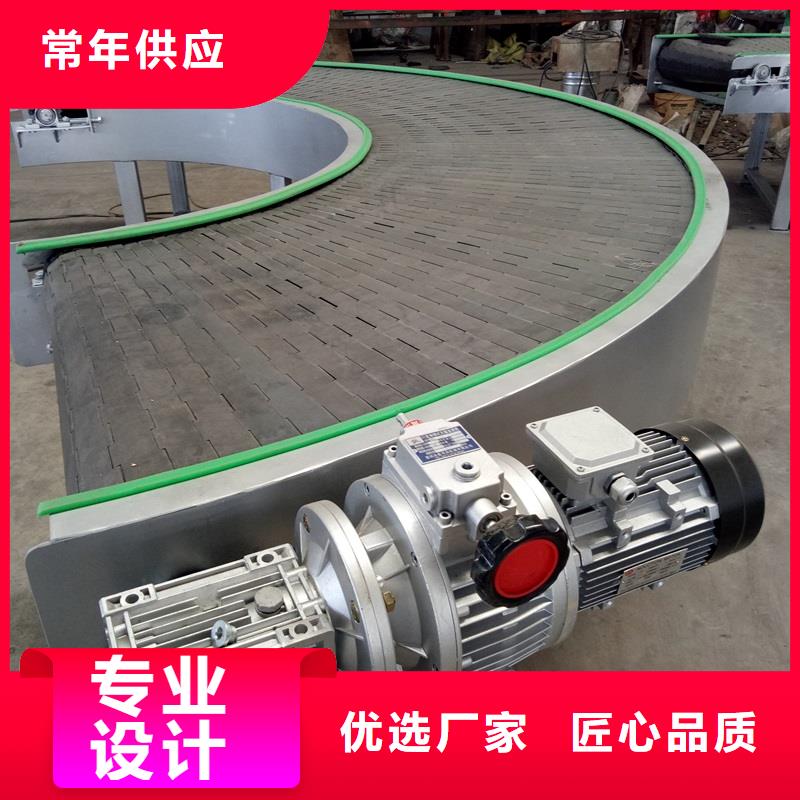

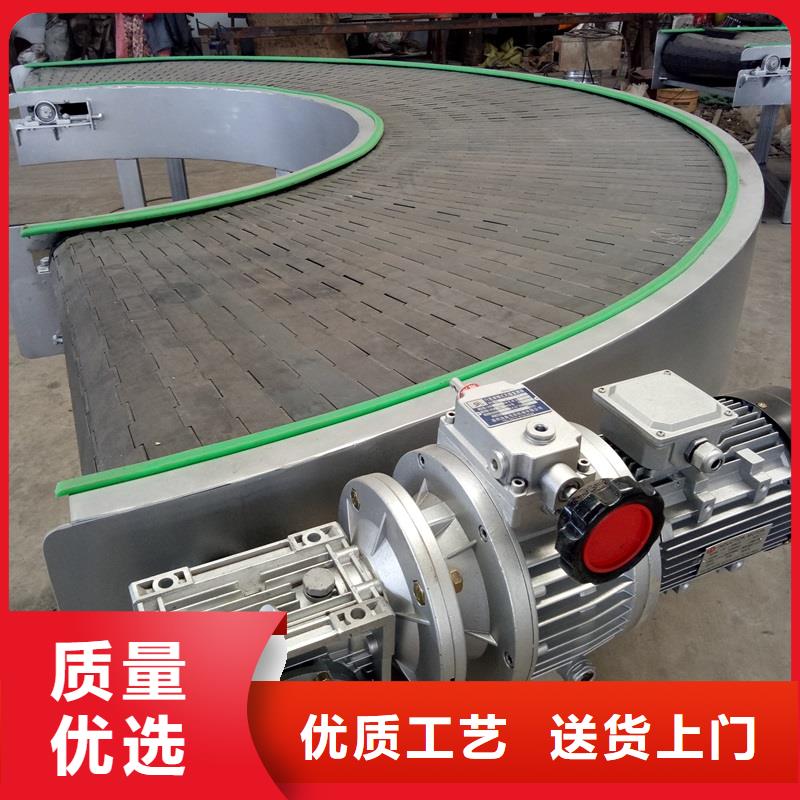

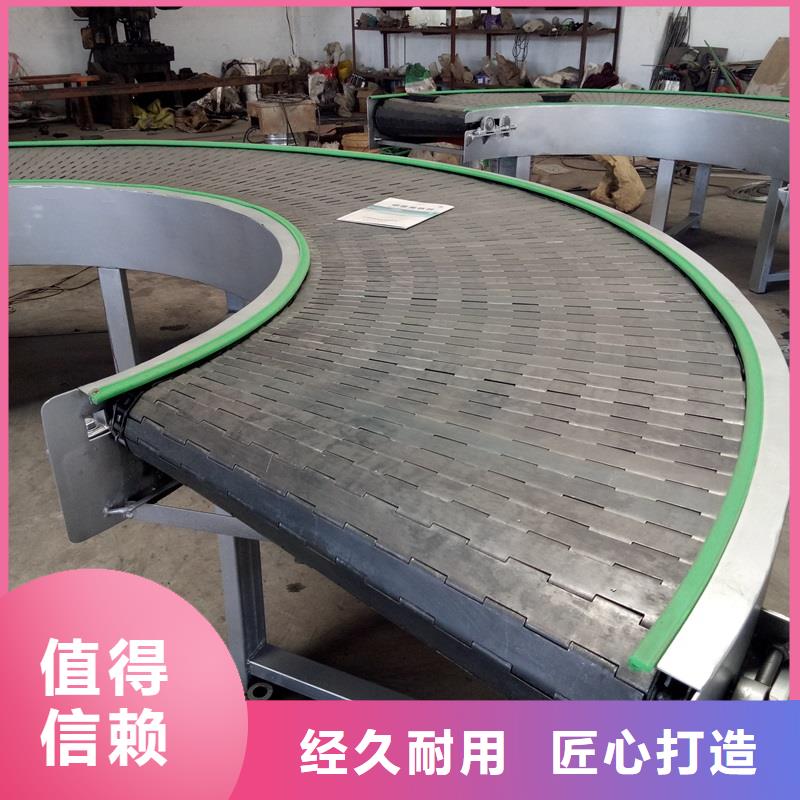

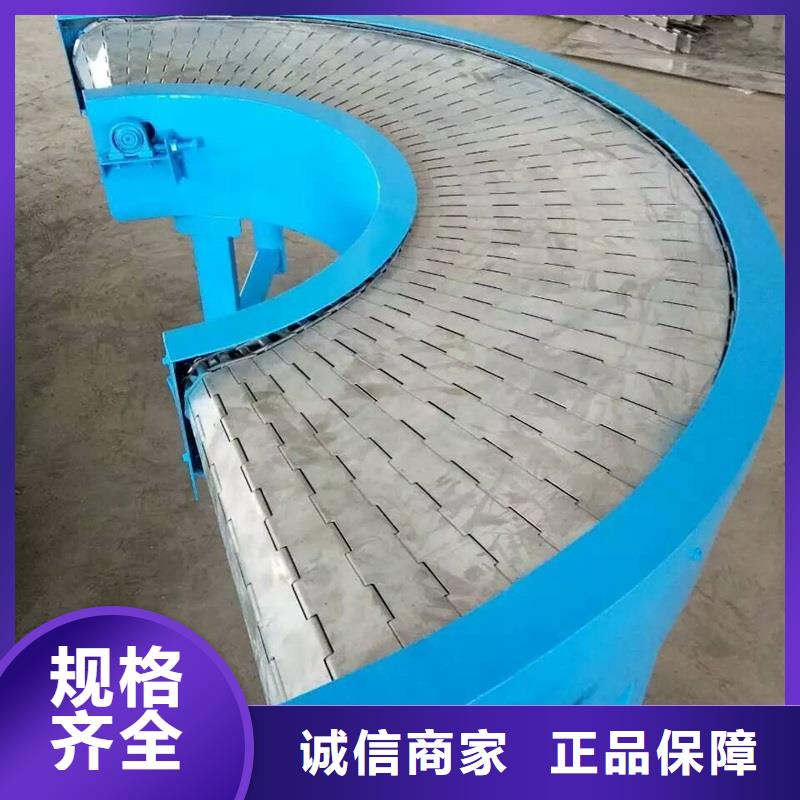

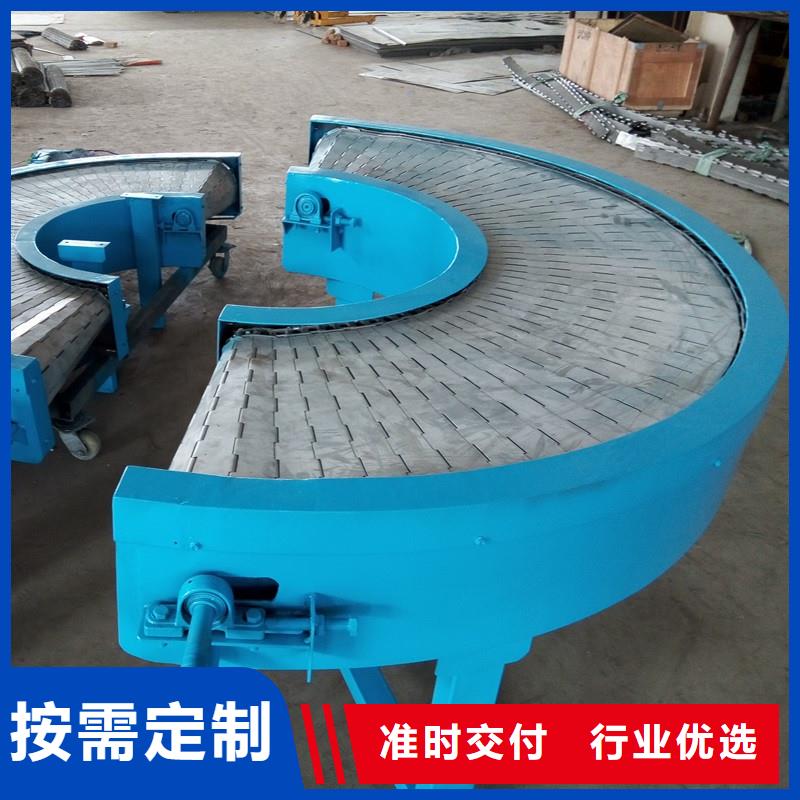

鏈板輸送機以標準鏈板為承載面,由馬達減速機為動力傳動;我們可以通過多列鏈板并行,使鏈板輸送機做的很寬并形成差速,利用多列鏈板的速度差使多列輸送在無擠壓的情況下變為單列輸送,從而滿足飲料貼標、灌裝、清洗等設備的單列輸送的要求,我們可以將兩條鏈板輸送機的頭尾部做成重疊式的混合鏈使得瓶(罐)體處于動態過度狀態,使輸送線上不滯留物料,可以滿足空瓶以及實瓶壓力和無壓力輸送。概述.鏈板輸送機鏈板規格:直輸鏈板寬度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;轉彎鏈板寬度有82.5、114.3、152.4、190.5、304.8。特點.1、鏈板輸送機的輸送面平坦光滑、摩擦力小,物料在輸送線之間的過渡平穩,可輸送各類玻璃瓶、PET瓶、易拉罐等物料,也可輸送各類箱包;2、鏈板有不銹鋼和工程塑料等材質、規格品種繁多,可根據輸送物料和工藝要求選用,能滿足各行各業不同的需求;3、機架材質分鋁型材、普通碳鋼、不銹鋼。4、輸送能力大,可承載較大的載荷,如用于電動車、摩托車、發電機等行業;5、輸送速度準確穩定,能保證的同步輸送;6、鏈板輸送機一般都可以直接用水沖洗或直接浸泡在水中,設備清潔方便,能滿足食品、飲料行業對衛生的要求;7、設備布局靈活。可以在一條輸送線上完成水平、傾斜和轉彎輸送;8、設備結構簡單,維護方便。應用.應用:直輸鏈板寬度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;轉彎鏈板寬度有82.5、114.3、152.4、190.5、304.8,廣泛用于食品、罐頭、藥品、飲料、和洗滌用品、紙制品、調味品、乳業及煙草等的自動輸送、分配、和后道包裝的連線輸送。輸送鏈板有POM材質和不銹鋼及不銹鐵3種,轉彎形式有帶翼轉彎和磁性轉彎2種。轉彎鏈板輸送機采用π型轉彎鏈板作為輸送載體,鏈板運行在高分子聚甲醛制作的專用轉彎導軌里;或使用不銹鋼轉彎鏈板并使用帶磁性的轉彎導軌,使輸送鏈板始終運行在專用導軌里面,具有運行平穩,安裝方便的特點;分類.鏈式輸送機主要分為鏈板輸送機、懸掛鏈輸送機、網帶輸送機、插件線輸送機四大類。設備簡介鏈板輸送機可以滿足飲料貼標、灌裝、清洗等設備的單列輸送的要求,同樣也可以使單列變成多列并行走緩慢,從而產生儲存量,滿足殺菌機、儲瓶臺、冷瓶機的大量供料的要求,我們可以將兩條鏈板輸送機的頭尾部做成重疊式的混合鏈,使得瓶(罐)體處于動態過度狀態,使輸送線上不滯留瓶子,可以滿足空瓶及實瓶的壓力和無壓力輸送。鏈板材質:碳鋼、不銹鋼、熱塑鏈,根據您的產品的需要可選取不同寬度、不同形狀的鏈板來完成平面輸送、平面轉彎、、下降等要求。鏈板規格:直輸鏈板寬度由63.5、82.5、101.6、114.3、152.4、190.5、254、304.8;轉彎鏈板寬度有82.5、114.3、152.4、190.5、304.8。懸掛鏈輸送機懸掛鏈是一種三維空間閉環連續輸送系統,適用于車間內部和車間之間成件物品的自動化輸送。根據輸送物件的方法,可分為通用和輕型的牽引式懸掛輸送、通用積放式和輕型積放式的推式懸掛輸送。 懸掛鏈,采用滾珠軸承作為鏈條走輪,導軌均選用16Mn材質經過深加工而成,使用壽命在5年以上。鏈條節距常用的有150/200/240/250等,單點承重也各不一樣。同時通過選擇吊具類型,可增加鏈條的單點承重。該輸送線能隨意轉彎、爬升,能適應各種地理環境條件。該輸送線主要用在車間內的物料空中配送上,設計合理的方案,能將倉庫、裝配線等相關節點有機的結合起來,可在程度上理順車間的物流,產生更大的效益。該輸送線也能用作摩托車車架的部裝,以及噴涂設備的烘干輸送設備。鏈板輸送機的使用注意事項.鏈板輸送機在飲料行業不僅給人們節約了時間,還帶來了方便,一個小小的輸送過程既滿足了飲料貼標、灌裝、清洗等要求,還有殺菌和存儲的作用。可是鏈板輸送機在使用的時候有些地方需要工作人員注意,如下:1、鏈板輸送機在運輸過程中運輸和儲存在物品運輸和儲存過程中注意不能和酸堿、油、水等污染物接觸,并且要遠離熱源;避免長期陽光直射和雨雪浸淋;儲存溫度應保持在–100C-400C,相對濕度應保持在50%-80%。運輸和儲存過程中不得擠壓、碰撞。2、鏈板輸送機的吊裝在使用吊車搬運鏈板輸送機的時候,采用繩索和鋼棒起吊的方式。先把一鋼棒穿過帶芯軸孔,并將帶有撐桿的繩索吊住鋼棒兩端將帶吊起。吊運時,注意勿使繩索損傷帶邊。在沒有鋼棒和撐桿的情況下,亦可將一具有足夠強度的織物繩索穿過芯軸孔起吊。但在繩索和帶接觸的地方,應墊一物體,防止繩索勒壞帶邊。不得將吊具插入帶卷內起吊,不得將繩索繞在帶卷上起吊,防止帶卷向一邊滑脫。也可使用有足夠承載能力的叉車搬吊,但不得使帶的外圈損傷。鏈板輸送機的日常維護.鏈板生產線設備清潔方便,線體可以直接用水沖洗設備的表面(但需注意動力部分及控制部分則不可用水清洗,以免損壞內部部件,觸電,發生意外事故。)要想使設備的使用壽命達到值,維護與保養才是關鍵。一般而言,動力部分的馬達在使用一年左右就需及時更換機油,以保證馬達處在運行狀態,減少內部的損耗。平時在鏈板生產線設備使用完后,要及時關閉電源,一段時間對設備表面進行清潔。設備需要維護時,應該由專業設備人員進行維護,非相關人員不要進行,以免發生造成不必要的經濟損失和事故。設備發生故障時不可盲目檢查維修,應讓專業工程人員來進行檢查維修。在輸送機運轉過程中,鏈板生產線遭受各種不一樣性質和體積的裁荷效用,居于極復雜的應力狀況下。鏈板生產線典型的毀壞方式有:工作面層和邊緣磨耗;受大塊礦巖沖擊效用引動擊穿、撕裂和脫落;芯體經過短笛和托輥組受反反復復屈曲應力引動疲乏;在背景媒介效用下,引動強度指標減低和老化等等。鏈板輸送機:又叫鏈板傳送機,鏈板線。是一種利用循環往復的鏈條作為牽引動力,以金屬板作為輸送承載體的一種輸送機械設備。國內市場上有兩種鏈板輸送機,一種是用鏈條,支軸和金屬板組成的輸送鏈板做成的輸送機;一種是用帶彎板的鏈條和金屬板組成的金屬板輸送帶做成的鏈板輸送機。鏈板式輸送機應用于重件的輸送,常用于各類摩托車、汽車總裝輸送線及焊接輸送機,各類制動器、發動機鏈板輸送機、起動機鏈板機、磁電器門鏈板輸送機、發電機鏈板輸送機、電焊機鏈板輸送機等裝配。輸送機為摩托車鏈板輸送機整車制造裝配廠商必不可少的設備,通過流水線操作,對工廠的裝配工藝進行有效的調整,合理分配每道工序;并可在輸送機上隨意添置在線檢測及自動裝配專機,實施有效的產品質量控制及設備運行狀態監控,為現代化的大生產提供必要的保障。輸送機采用大節距滾針彎板鏈為輸送介質,拖動金屬面板作循環往復運行,鏈板輸送線的速度可調。有照明、風扇、工裝板等標準配置。根據產量對線體的長度進行選擇。鏈板輸送線是以大節距特種彎板鏈條為傳送介質,帶動金屬/塑料面板作循環往復運行的一種輸送裝配設備。由于線體結構及輸送介質較為堅固,所以一般用在較重物品的輸送和裝配作業現場,每米的承重可達到500Kg。線體的輸送速度可調,有電磁調速、變頻調速、機械調速等各種調速方式,一般快速度在15M/min以內。由于工作環境以及生產工藝的需要,該線體也可做成90度或180度轉彎型的,用在空調鏈板輸送機、冰箱鏈板鏈板機、電動工具鏈板輸送機等的抽真空、檢測上。在面板上可設置各種工裝夾具,以滿足工件的夾緊、旋轉及裝配、檢測等。在需要對工件表面進行防護的,面板可采用塑料材質或是在金屬面板表面貼膠。線體的主體結構主要有鋼架結構和鋁型材結構兩種。傳送鏈條的節距從38.1mm到200mm可供選擇。是重型物品輸送裝配作業現場為理想的設備。鏈板式輸送機,利用固接在牽引鏈上的一系列鏈板在水平或傾斜方向輸送物料的輸送機,以單片鋼板鉸接成環帶作為運輸機的牽引和承載構件承載面具有橫向隔片置于槽箱中驅動環帶借隔片將煤刮運輸出。它由驅動機構、張緊裝置、牽引鏈、板條、驅動及改向鏈輪、機架等部分組成。在冶金、煤炭、化工、電力、機械制造及國民經濟的其他工業部門中均得到了廣泛的應用。特點.1、適用范圍廣。除粘度特別大的物料外,一般固態物料和成件物均可用它輸送;2、輸送能力大;3、牽引鏈的強度高,可用作長距離輸送;4、輸送線路布置靈活。與網帶式輸送機相比,鏈板式輸送機可在較大的傾角和較小的彎曲半徑的條件下輸送,因此布置的靈活性較大。鏈板式輸送機的傾角可達30°-35°,彎曲半徑一般約為5-8m;5、在輸送過程中可進行分類、干燥、冷卻或裝配等各種工藝加工;6、運行平穩可靠;分類.1、鏈板式輸送機的結構型式多樣。鏈板式輸送機一般可按下述分類:2、按輸送機的安裝形式可分為固定式和移動式;3、按輸送機的布置形式可分為水平型、水平-傾斜型、傾斜型、傾斜-水平型、水平-傾斜-水平型等;4、按牽引構件的結構型式可分為套筒滾子鏈式、沖壓鏈式、鑄造鏈式、環鏈式及可拆鏈式等;5、按牽引鏈的數量可分為單鏈式和雙鏈式;6、按底板的結構型式可分為鱗板式(有擋邊波浪型,無擋邊波浪型,有擋邊深型等)和平板式(有擋邊平型和無擋邊平型等);7、按輸送機的運行特征可分為連續式和脈動式;8、按驅動方式可分為電力機械驅動式及液力驅動式。特點.占地面積小,伸縮自如;*方向易變,可靈活改變輸送方向,時可達到180度;*S型輥道輸送機,每單元由8只輥筒組成,每一個單元都可獨立使用,也可多個單元聯接使用,安裝方便;*S型輥道輸送機伸縮自如,一個單元長與短狀態之比可達到3倍;*S型輥道輸送機可靈活改變輸送方向,時可以大于180度。滾筒輸送機適用于各類箱、包、托盤等件貨的輸送,散料、小件物品或不規則的物品需放在托盤上或周轉箱內輸送。能夠輸送單件重量很大的物料,或承受較大的沖擊載荷。結構形式:按驅動方式可分為動力滾筒線和無動力滾筒線,按布置形式可分為水平輸送滾筒線、傾斜輸送滾筒 線和轉彎滾筒線。還可按客戶要求特殊設計,以滿足各類客戶的要求。標準規滾筒線內寬度為200、300、400、500、1200mm等。也可按客戶需求 采用其它特殊規格。轉彎滾筒線標準轉彎內半徑為600、900、1200mm等,也可按客戶需求采用其它特殊規格。直段滾筒所用的滾筒直徑有38、50、 60、76、89mm等。特點1、鏈板輸送機的輸送面平坦光滑、摩擦力小,物料在輸送線之間的過渡平穩,可輸送各類玻璃瓶、PET瓶、易拉罐等物料,也可輸送各類箱包 ;2、鏈板有不銹鋼和工程塑料等材質、規格品種繁多,可根據輸送物料和工藝要求選用,能滿足各行各業不同的需求;3、機架材質分鋁型材、普通碳鋼、不銹鋼。4、輸送能力大,可承載較大的載荷,如用于電動車、摩托車、發電機等行業;板式輸送機生產 鏈板式輸送機圖片制造廠家5、輸送速度準確穩定,能的同步輸送;板式輸送機生產 鏈板式輸送機圖片制造廠家鏈板式運輸機,裝配鏈板輸送機6、鏈板輸送機一般都可以直接用水沖洗或直接浸泡在水中,設備清潔方便,能滿足食品、飲料行業對衛生的要求;和洗滌用品,使輸送鏈板始終運行在導軌里面,注意勿使繩索損傷帶邊,設備結構簡單7、設備布局靈活。可以在一條輸送線上完成水平、傾斜和轉彎輸送;8、設備結構簡單,維護方便。選擇方法可根據需要選用相應材質和寬度的鏈板 。1.參照輸送產品-平板鏈來選型板式輸送機生產 鏈板式輸送機圖片制造廠家,鏈板線廠家2.選用不同形式的平板鏈,可實現平面輸送、平面轉彎、下降等各種功能。在使用吊車搬運鏈板輸送機的時候,清洗等設備的單列輸送的要求。3.電機可根據需要設置在機架下面或機架上面。加厚鐵板式運輸機減少內部的損耗,從而產生儲存量,輸送量要求等4.速度調節可選擇變頻調速或選用無級變速減速電機。板式輸送機生產 鏈板式輸送機圖片制造廠家,鏈板爬坡輸送機5.輸送機可設置側面擋板,兩側安裝控制工位單元,實輸送過程的自動化功能。6.根據提供的詳細輸送物料名稱、尺寸和要求機器的材質、尺寸、速度、輸送量要求等日常維護鏈板生產線設備清潔方便,線體可以直接用水沖洗設備的表面(但需注意動力部分及控制部分則不可用水清洗,以免損壞內部部件,觸電,發生意外事故。)要想使設備的使用壽命達到大值,維護與保養才是關鍵。一般而言,動力部分的馬達在使用一年左右就需及時更換機油,以馬達處在佳運行狀態,減少內部的損耗。平時在鏈板生產線設備使用完后,要及時關閉電源,一段時間對設備表面進行清潔。設備需要維護時,應該由設備人員進行維護,非相關人員不要進行,以免發生造成不必要的經濟損失和事故。設備發生故障時不可盲目檢查維修,應讓工程人員來進行檢查維修。在輸送機運轉過程中,鏈板生產線遭受各種不一樣性質和體積的裁荷效用,居于極復雜的應力狀況下。鏈板生產線典型的毀壞方式有:工作面層和邊緣磨耗;受大塊礦巖沖擊效用引動擊穿、撕裂和脫落;芯體經過短笛和托輥組受反反復復屈曲應力引動疲乏;在背景媒介效用下,引動強度指標減低和老化等等。工作原理鏈板式輸送機 ,由動力裝置(電機)、傳動軸、滾筒、張緊裝置、鏈輪、鏈條、軸承、潤滑劑、鏈板等等構成。其中帶動物料的輸送的主要的兩個部分為:鏈條,利用它的循環往復運動提供牽引動力;金屬板,作為輸送過程中的承載體。其原理主要是利用固接在牽引鏈上的一系列鏈條提供牽引力,用金屬板作承載體物料隨著水平或者傾斜方向輸送。鏈板式輸送機被廣泛運用于各行各業之中,電力、冶金、釀酒、化工、醫療、機械制造等等寬廣的領域。為滿足生產現場的各種需求,我們可以對自動化線中的輸送機器進行具體設計,來達到要求和目的。板式輸送機生產 鏈板式輸送機圖片制造廠家鏈板生產線,擋板式鏈板輸送機由動力裝置(電機),應該由設備人員進行維護因公司皮帶機,斗式機,螺旋輸送機,管式輸送機,氣力輸送機等輸送機械生產的規模化。所有配件自產,量產化。包括槽形托輥.平行托輥.錐形調心托輥.摩擦調心托輥.回程托輥.尼龍托輥.不銹鋼托輥.橡膠托輥.鉸接托輥.支架支柱.沖承座.密封件.橡膠圈.包膠滾筒.傳動滾筒.改向滾筒.電動滾筒.逆止器.連軸器.跑偏開關.拉繩開關.頭架尾架.中間架支腿的量產。食品輸送帶,耐高溫輸送帶。阻燃輸送帶,pvc 輸送帶防滑輸送帶,耐酸、耐堿輸送帶,聚酯輸送帶,尼龍輸送帶流水線的規模生產,特鋼螺旋s葉片,板式鏈條【斗式機,管式輸送機,各種刮板輸送機】生產線的量產化,斗提沖壓畚斗,各類塑料畚斗,管式輸送機塑料盤片生產線陸續投產、真正實現了廠家,直接與用戶見面,簡化縮短了流通過程.一、鏈板輸送機主要特點該機為消化吸收國外先進技術而規劃定型 不銹鋼鏈板輸送機標準,主要特點有:1.傾角大:用于運送散狀廢紙可達30O;運送捆狀廢紙的傾角≤22O。2.易損件少:易損件只要粉末冶金含油軸承 不銹鋼鏈板輸送機,且也十分耐磨。3.承載力強:長軸、短軸外用了優異合金鋼套。4.用材考究:如軌跡為輕軌 不銹鋼鏈板運送機原料,拉緊設備用螺絲、螺桿為不銹鋼材質等。5.光滑方法共同。鋼套與軸的相對運動幾乎沒有,使表里鏈板壽數大大提高。6.槽底板:采用雙圓弧板,與各種鏈板運送機天壤之別。7.槽底板兩頭加擋邊,使偶爾呈現的少數小塊狀物料不會從兩頭漏出。8.槽底板一概運用一次成型的沖壓件。鏈板輸送機中的運送速度能夠改動嗎?鏈板輸送機中的運送速度能夠依照生產工藝的請求操作。構件尺度:運送機的構件尺度包含運送帶寬度、板條寬度、料斗容積、管道直徑和容器巨細等。這些構件尺度都直接影響運送機的運送才能。運送長度和傾角:運送線路長度和傾角巨細直接影響運送機的總阻力和所需求的功率。板鏈輸送機以標準板鏈為承載面,由馬達減速機為動力傳動,運行在專用導軌中,根據工藝流程及材質不同,板鏈輸送機分為平板鏈輸送機,爬坡板鏈輸送機,頂板鏈輸送機和塑鋼鏈輸送機,廣泛應用于食品、罐頭飲料、洗滌產品等行業,它可滿足貴公司所需的自動輸送、分級包裝、耐磨、防腐、結構精密、運行平穩。板式鏈輸送機不銹鋼輸送機地毯清洗機打孔鏈板輸送機板式鏈輸送機不銹鋼輸送機地毯清洗機打孔鏈板輸送機, 地毯清洗機打孔鏈板運送帶局部損人造棉應用時修補避免呈現擴大;不銹鋼網帶在呈現跑偏時采納辦法糾正;運送的過程中不能帶負荷發動;鏈板不銹鋼運送帶的運用,要避免托輥被物料覆蓋,避免其形成回轉不靈漏料卡于滾筒與不銹鋼運送帶之間,轉動部分的光滑不可以污染了不銹鋼網帶。 出產線鏈板運送帶職業也在發生著飛速的改變與改革,不銹鋼鏈板運送帶更好的習慣不同職業的需求,開始規劃的時分要充沛考慮到各方面的需求。依據詳細參數規劃出的運送線鏈板才能更好的習慣各職業的。運送線鏈板運送帶需求運送的物料的性質及載重的運送能力,在傳遞成件物品時成見物品的分量和尺度要知道等等;還需求考慮到該設備運用環境,看看它是在露天、室內、干燥、濕潤 、環境溫度和空氣含塵量巨細等等的哪種環境下運用出產的;鏈板運送機的卸料方法和卸料設備的構成、受料點數目及方位的問題也是需求考慮的問題;不銹鋼網帶運送機裝置的形式以及相關尺度包括運送線鏈板運送帶的長度、提高高度以及傾角等。 金屬排屑鏈板輸送機板式鏈傳送帶機床附件輸送機金屬排屑鏈板輸送機板式鏈傳送帶機床附件輸送機鏈板輸送機的設備通用化、操作簡略、修理起來也對比簡單、運轉牢靠、拆裝也便利。一同也能夠和別的的一些排屑設備一同運用,構成各種方式擺放的切削處理系統。鏈板排屑機具有運送功率高,運送速度挑選規模大、流線外型,美觀大方,排屑順利的特色。我公司從事輸送機械設備多年,致力于包裝設備、運送設備、整線工程等自動化設備的發與制作。的技術優勢與的設備質量深受用戶的期待和信任;長期以來,全眾公司消化、吸收并掌握世界的加工技術與包裝機械的前沿技術;的規劃理念及工程實績,提供給各企業的生產后勤援助。跟著生產功率的不斷發展。不銹鋼鏈板輸送機不斷增加的出現在了工業生產中,在穩步發脹的運送機工業中,大家越來越留意不銹鋼鏈板輸送機的工作功率等一系列問題,那么咱們應當挑選什么樣的不銹鋼鏈板輸送機呢?不銹鋼鏈板輸送機能夠滿意飲料貼標、灌裝、清潔等設備的單列運送的請求,相同也能夠使單列成為多列并行走緩慢,然后產生儲存量,滿意殺菌機、儲瓶臺、冷瓶機的很多供料的請求。我廠生產的不銹鋼網帶輸送機的運送面平整潤滑,摩擦力小,物料在運送線之間的過渡平穩,可運送各類玻璃瓶、PET瓶、易拉罐等物料。鏈板采用不銹鋼和工程塑料等原料,可根據需要滿意各行各業不一樣的需要。強壯的運送能力,可承載較大的載荷。準確穩定的運送速度能確保準確的同步運送。靈敏的設備布局可在一條運送線上完結水平、傾斜和轉彎運送。 鑄造件輸送機重型鏈板輸送機扣板鏈板輸送機小型板式鏈輸送機鑄造件輸送機重型鏈板輸送機扣板鏈板輸送機小型板式鏈輸送機鑄造件運送機:也叫鑄造件傳送帶,運送帶,鏈條運送機,鏈板運送機,運送傳動架子,流水線,自動化運送線,鑄造件傳料機械。鍛件件運送機便是用來運送高溫1250度左右高溫鑄造件,鍛壓件的。鑄造件運送機的長處便是可以運送高溫件,不變形,耐高溫,耐沖擊力,抗砸,鏈板運送機的運送帶采用運送高溫鑄造件的不銹鋼鏈板,鑄造件運送機速度可調,可調規模從0.025米-60米/分鐘,運送機高度可調,一般是15公分可調規模,鑄造件運送機械我們研發了四種:合頁鏈板運送機,平頂鏈鏈板運送機,槽鋼隔板鏈板運送機,多片鏈條運送機。鑄造件鏈板運送機可以做成水平直輸的,提高爬坡的,拐彎的。 定做鏈板運送機需求客戶提供的數據 1,鏈板運送機長度,寬度,高度,速度 2,運送物件的分量,大小,溫度,形狀 3,運送帶的運轉速度,可調規模 4,運送機有附件要求嗎? 不銹鋼鏈板輸送機鏈條傳動帶式輸送機板式鏈輸送帶傳送機1、不銹鋼鏈板制作過程中的高速沖載和多顆落料技術在職業已獲得主導地位。中大標準鏈板或修孔,或鋼球擠孔,或二次沖孔,耐高溫不銹鋼鏈板報價,后兩種都是世界水平。2、不銹鋼鏈板沖孔落料模具的的原料得到了優化,硬質合金化。選用光飾機進行鏈板拋光去毛刺,耐高溫不銹鋼鏈板,使得在裝置使用過程中不會去掛檫物品3、銷軸高速堵截技術在不斷的晉級。為了更快更的拼裝不銹鋼鏈板對銷軸倒角技術的研討。4、在套筒的選用加工方面:中大標準尺度的用無縫管,中小標準選用卷制,優法為比勒機和MRP預彎法,重要鏈條套筒也可用冷擠壓辦法制作。產品主要特點:不銹鋼鏈板現在已經逐步得到了廣泛的應用,對于該鏈板的性能,大家應該都不陌生了,不過在應用過程中一些用戶向我們反映不銹鋼鏈板表面會有一些銹斑,這時我們應該如何有效去除銹斑呢,接下來為大家詳細說明下:去除不銹鋼鏈板表面的銹斑,可以使用酸洗膏,能夠提高不銹鋼鏈板表面的光潔度,在其表面形成一層致密完整,耐高溫不銹鋼鏈板批發,附著力強的鈍化膜,可以有效延長不銹鋼鏈板的使用壽命,還適用于化工機械、食品機械、印染機械、制藥機械、壓力容器制造及干燥設備、化工設備及化工設備安裝等行業使用、工程構件等表面處理。 新型鏈板輸送機機械板鏈輸送線重工板式鏈傳送帶不銹鋼鏈板的產業鏈已廣泛應用在鋼鐵行業,而它運行過程中呈現的情況一直是咱們的技術人員頭疼的問題,其中為常見的就是沖突問題。為此,公司也做了不少的研討工作。今日,小編與我們分享一下對于不銹鋼鏈板運行過程中的沖突問題的解決方法。近,又一次的探討和研討后,公司技術人員為了下降不銹鋼鏈之間的沖突和磨損的沖突,削減沖突阻力減摩資料采用了多種潤滑資料。潤滑油,油脂,固體潤滑劑。在變速器潤滑劑鏈的選擇時,首先要考慮的形式,合適的環境溫度,潤滑鏈規范。潤滑油在運用不銹鋼鏈可以用gb443 64機械油,鏈浸透防銹潤滑油在工廠中,為了避免滴油保管運輸損耗,常參加潤滑油的增稠劑,一般每個廠家都自調制,作者用了一個退讓方案了其防銹潤滑功能。不銹鋼鏈板是我們十分熟悉的修建鋼材,那么什么使不銹鋼鏈板具有較強的防腐功能呢?據研討不銹鋼鏈板的抗腐蝕性取決于上面所說的耐氧化的金屬鉻,可是,鉻含量更高時,雖然仍可提高其耐腐蝕的功能,但并不是很明顯。原因是用鉻對鋼進行合金化的處理時,把其外表氧化物的類型改變成了相當于純鉻金屬上形成的外表氧化物。這種緊密粘附的富鉻氧化物保護外表,避免進一步地氧化。重型鏈板輸送機汽車配件組裝生產線板式鏈輸送帶 鏈板輸送機分為:重型鏈板輸送機有時也稱為隔板運送機,它通常作為地上物流運送設備。重型鏈板機適用于、摩托車、家電(電視機、洗衣機、電冰箱等)、大型電器、機電等作業。重型板鏈運送機通常可與懸掛運送機、滾筒運送機、機等構成立體自動化出產線,充分運用各自的長處,以抵達前進出產功率,下降勞動本錢,產品質量的成效,是現代大型企業整廠自動化出產好的組合辦法。輕型板鏈運送機也稱為頂板鏈運送機或平頂鏈運送機。輕型板鏈運送機廣泛適用于食物、飲料、電子、電器及輕工作業。輕型板鏈運送機具有十分活絡的運送辦法,它能充分有效地運用空間,既可規劃成各種機型獨自運用,又能十分便當地和別的運送設備配套。輕型鏈板運送機主要特征:構造輕盈、工作平穩、噪音低、保護便當。 重型鏈板機運送鏈板資料有:不銹鋼、碳鋼、鋁合金。機架資料通常用碳鋼資料。現在,中國自立立異研制的鏈板輸送機,在國際化開展日趨成熟的大布景下,市場規模不斷拓展,并逐漸向海外進軍,開端向東南亞、非洲、拉美等領域延伸。但是,現階段正值中國經濟社會開展的首要戰略機會期,工業作為能源消耗及環境污染的首要領域,在加速建造資源節約型和環境友好型系統的束縛下,面對轉型晉級的戰略性開展機會,鏈板輸送機亦是如此,開端向清洗化、低耗能化、化、大型化開展。 不銹鋼鏈板沖孔耐高溫輸送帶食品輸送機流水線烘干鏈板廠家板式鏈1.烘干鏈板在機械、運輸等行業中的作用鏈板輸送機在實際運用上能夠完成飲料貼標、灌裝、清洗等設備的單列輸送的要求,并且可以使單列變成多列并,這樣一來就能夠滿足殺菌機、儲瓶臺、冷瓶機的大量供料的要求,我們一般把兩條鏈板輸送機的頭相接組成混合鏈,這樣就能使得輸送物品處于動態過度狀態,避免了輸送線上的瓶子滯留問題,達到空瓶及實瓶的無壓力輸送。德州鏈板廠家加工烘干鏈板2.不銹鋼鏈板沖孔特點說明1)輸送能力大,承載物品質量比較大,能夠滿足很多電車和食品等行業的輸送需要2)輸送的度達到一種很高的境界,對于精密物品的輸送很適合 3)沖孔鏈板的清潔工作比較簡潔方便,很輕松的實現食品、飲料行業對衛生的要求。 4)靈活性比較好。在一條輸送線上能夠同時完成水平、傾斜和轉彎輸送的高難度活動。 【鏈板輸送機說明】 鏈板輸送機/網鏈輸送機/鏈板輸送線/鏈板流水線廣泛適于用于食品、罐頭、藥品、飲料、和洗滌用品、紙制品、調味品、乳業及煙草等的自動輸送、分配、和后道包裝的連線輸送。鏈板式輸送機可以滿足飲料貼標、灌裝、清洗等設備的單列輸送的要求,滿足殺菌機、儲瓶臺、冷瓶機的大量供料的要求,可將兩條鏈板輸送機的頭尾部做成重疊式的混合鏈,使得瓶(罐)體處于動態過度狀態,使輸送線上不滯留瓶子,可以滿足空瓶及實瓶的壓力和無壓力輸送。 ·規格:1.直輸鏈板寬度有63.5、82.5、101.6、114.3、152.4、190.5、254、304.8; ·· 2.轉彎鏈板寬度有82.5、114.3、152.4、190.5、304.8。 ·材質:碳鋼、不銹鋼、塑鋼,根據產品的需要可選取不同寬度、不同形狀的鏈板來完成平面輸送、平面轉彎、、下降等要求。主要特點:1、鏈板輸送機/鏈板輸送線/鏈板流水線的輸送面平坦光滑,摩擦力小,物料在輸送線之間的過渡平穩。2、鏈板有不銹鋼和工程塑料等材質,規格品種繁多,可根據輸送物料和工藝要求選用,能滿足各行各業不同的需求。 3、輸送速度準確穩定,能保證的同步輸送。 4、鏈板輸送機/鏈板輸送線/鏈板流水線一般都可以直接用水沖洗或直接浸泡在水中。設備清潔方便,能滿足食品、飲料行業對衛生的要求。 5、設備布局靈活。可以在一條輸送線上完成水平、傾斜和轉彎輸送。 6、設備結構簡單,維護方便。 The chain plate conveyor takes the standard chain plate as the bearing surface and is driven by the motor reducer; We can make the chain plate conveyor very wide and form a differential speed through the parallel operation of multiple chain plates, and use the speed difference of multiple chain plates to change the multi row conveyor into a single row conveyor without extrusion, so as to meet the requirements of single row transportation of beverage labeling, filling, cleaning and other equipment. We can make the head and tail of the two chain plate conveyors into overlapping hybrid chains to make bottles (cans) The body is in a dynamic transition state, so that there is no material left on the conveying line, which can meet the pressure and non pressure conveying of empty bottles and solid bottles. summary. Chain plate specification of chain plate conveyor: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. characteristic. 1. The conveying surface of the chain plate conveyor is flat and smooth, the friction is small, and the transition of materials between the conveying lines is stable. It can transport all kinds of glass bottles, PET bottles, cans and other materials, as well as all kinds of bags; 2. The chain plate has a wide variety of materials and specifications such as stainless steel and engineering plastics, which can be selected according to the conveying materials and process requirements, and can meet the different needs of all walks of life; 3. The frame material is divided into aluminum profile, ordinary carbon steel and stainless steel. 4. Large conveying capacity and can carry large loads, such as electric vehicles, motorcycles, generators and other industries; 5. The conveying speed is accurate and stable, which can ensure accurate synchronous conveying; 6. Generally, the chain plate conveyor can be directly washed with water or soaked in water. The equipment is clean and convenient, and can meet the hygienic requirements of the food and beverage industry; 7. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line; 8. The equipment has simple structure and convenient maintenance. Application Application: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. It is widely used for automatic transportation, distribution and connecting transportation of subsequent packaging of food, cans, drugs, beverages, cosmetics and washing products, paper products, condiments, dairy and tobacco. There are three kinds of conveyor chain plates: POM material, stainless steel and stainless iron. There are two kinds of turning forms: Wing turning and magnetic turning. The π type turning chain plate is used as the conveying carrier for the turning chain plate conveyor, and the chain plate runs in the special turning guide rail made of high molecular polyformaldehyde; Or use stainless steel turning chain plate and magnetic turning guide rail to make the conveying chain plate always run in the special guide rail, which has the characteristics of stable operation and convenient installation; Classification Chain conveyors are mainly divided into four categories: chain plate conveyor, hanging chain conveyor, mesh belt conveyor and plug-in line conveyor. Equipment introduction The chain plate conveyor can meet the requirements of single row transportation of beverage labeling, filling, cleaning and other equipment. It can also turn a single row into multiple rows and walk slowly, so as to generate storage capacity and meet the requirements of large amount of feeding of sterilizer, bottle storage table and bottle cooler. We can make the head and tail of the two chain plate conveyors into overlapping mixing chains to make bottles (cans) The body is in a dynamic transition state, so that there are no bottles on the conveying line, which can meet the pressure and non pressure conveying of empty bottles and solid bottles. Chain plate material: carbon steel, stainless steel and thermoplastic chain. According to the needs of your products, chain plates with different widths and shapes can be selected to meet the requirements of plane transportation, plane turning, lifting and lowering. Chain plate specification: the width of direct chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254 and 304.8; The width of turning chain plate is 82.5, 114.3, 152.4, 190.5 and 304.8. Hanging chain conveyor Suspension chain is a three-dimensional closed-loop continuous conveying system, which is suitable for the automatic conveying of finished goods within and between workshops. According to the method of conveying objects, it can be divided into general and light traction suspension conveying, general stacking type and light stacking type push suspension conveying. The suspension chain adopts ball bearing as the chain running wheel, and the guide rails are made of 16Mn material through deep processing, with a service life of more than 5 years. The chain pitch commonly used is 150 / 200 / 240 / 250, and the single point load-bearing is also different. At the same time, the single point load-bearing of the chain can be increased by selecting the type of spreader. The conveyor line can turn and climb at will, and can adapt to various geographical environment conditions. The transmission line is mainly used for the air distribution of materials in the workshop. A reasonable scheme can organically combine the warehouse, assembly line and other relevant nodes, straighten out the logistics of the workshop to the greatest extent and produce greater benefits. The conveying line can also be used as part of motorcycle frame and drying conveying equipment of spraying equipment. Precautions for use of chain conveyor In the beverage industry, the chain plate conveyor not only saves people time, but also brings convenience. A small conveying process not only meets the requirements of beverage labeling, filling and cleaning, but also plays the role of sterilization and storage. However, when the chain plate conveyor is used, some places need the attention of the staff, as follows: 1. The chain plate conveyor is transported and stored during transportation During transportation and storage, pay attention not to contact with acid-base, oil, water and other pollutants, and keep away from heat source; Avoid long-term direct sunlight and rain and snow; The storage temperature shall be maintained at – 100c-400c and the relative humidity shall be maintained at 50% - 80%. Do not squeeze or collide during transportation and storage. 2. Hoisting of chain plate conveyor When using a crane to carry the chain conveyor, it is best to use rope and steel rod lifting. Firstly, put a steel rod through the hole with mandrel, and hang the rope with stay rod at both ends of the steel rod. When lifting, pay attention not to damage the belt edge with the rope. A fabric rope with sufficient strength can also be lifted through the mandrel hole without steel rod and stay rod. However, an object shall be padded at the place where the rope contacts the belt to prevent the rope from damaging the belt edge. Do not insert the spreader into the coil for lifting, and do not wind the rope around the coil for lifting, so as to prevent the coil from slipping to one side. A forklift with sufficient bearing capacity can also be used for lifting, but the outer ring of the belt shall not be damaged. Daily maintenance of chain conveyor The equipment of the chain plate production line is easy to clean, and the line body can directly wash the surface of the equipment with water (but it should be noted that the power part and control part can not be cleaned with water to avoid damaging internal parts, electric shock and accidents). Maintenance and maintenance is the key to maximize the service life of the equipment. Generally speaking, the engine oil of the motor of the power part needs to be changed in time after it has been used for about one year, so as to ensure that the motor is in the best running state and reduce internal loss. Usually, after the chain plate production line equipment is used, the power supply shall be turned off in time and the equipment surface shall be cleaned for a period of time. When the equipment needs maintenance, it should be maintained by professional equipment personnel, not by non relevant personnel, so as to avoid unnecessary economic losses and safety accidents. In case of equipment failure, do not blindly check and repair, but let professional engineers check and repair. During the operation of the conveyor, the chain plate production line suffers from various load cutting effects with different properties and volumes, living in extremely complex stress conditions. The most typical destruction modes of chain plate production line are: working surface course and edge wear; Breakdown, tearing and falling off caused by the impact of large ore and rock; The core is fatigued by repeated buckling stress after passing through the piccolo and idler group; Under the background media utility, the index of actuation strength decreases and ages. Chain plate conveyor: also known as chain plate conveyor, chain plate line. The utility model relates to a conveying mechanical equipment which uses a circular chain as the traction power and a metal plate as the conveying bearing body. There are two kinds of chain plate conveyors in the domestic market. One is the conveyor made of chain plate composed of chain, supporting shaft and metal plate; One is a chain plate conveyor made of metal plate conveyor belt composed of chain with bending plate and metal plate. Chain plate conveyor is applied to the transportation of heavy parts, and is often used for the assembly of all kinds of motorcycles, automobile assembly conveyor lines and welding conveyors, all kinds of brakes, engine chain plate conveyor, starter chain plate machine, magnetoelectric door chain plate conveyor, generator chain plate conveyor, electric welding machine chain plate conveyor, etc. The conveyor is an indispensable equipment for the whole motorcycle chain conveyor manufacturer. Through assembly line operation, the assembly process of the factory is effectively adjusted and each process is reasonably distributed; In addition, special machines for on-line detection and automatic assembly can be added on the conveyor at will to implement effective product quality control and equipment operation status monitoring, so as to provide necessary guarantee for modern mass production. The conveyor adopts the large pitch needle roller bending chain as the conveying medium, drives the metal panel for circular operation, and the speed of the chain plate conveying line is adjustable. There are standard configurations such as lighting, fan and tooling board. The length of the thread body is selected according to the output. The chain plate conveyor line is a kind of conveying and assembly equipment which takes the large pitch special bending chain as the transmission medium and drives the metal / plastic panel to run circularly. Because the line structure and conveying medium are relatively solid, it is generally used in the conveying and assembly site of heavy goods, and the maximum load per meter can reach 500kg. The conveying speed of the line body is adjustable, including electromagnetic speed regulation, frequency conversion speed regulation, mechanical speed regulation and other speed regulation modes. Generally, the fastest speed is within 15m / min. Due to the needs of working environment and production process, the line can also be made into 90 degree or 180 degree turning type, which can be used for vacuum pumping and detection of air conditioning chain conveyor, refrigerator chain conveyor, electric tool chain conveyor, etc. Various tooling fixtures can be set on the panel to meet the clamping, rotation, assembly and detection of workpieces. Where the surface of the workpiece needs to be protected, the panel can be made of plastic or pasted on the surface of the metal panel. The main structure of the line body mainly includes steel frame structure and aluminum profile structure. The pitch of the conveyor chain can be selected from 38.1mm to 200mm. It is the most ideal equipment for the transportation and assembly of heavy goods. The chain plate conveyor uses a series of chain plates fixedly connected to the traction chain to transport materials in the horizontal or inclined direction. A single steel plate is hinged into a ring belt as the traction and bearing component of the conveyor. The bearing surface is provided with a transverse spacer placed in the tank to drive the ring belt to scrape and transport the coal through the spacer. The utility model is composed of a driving mechanism, a tensioning device, a traction chain, a lath, a driving and reversing sprocket, a frame, etc. It has been widely used in metallurgy, coal, chemical industry, electric power, machinery manufacturing and other industrial sectors of the national economy. characteristic. 1. Wide range of application. Except for materials with high viscosity, general solid materials and finished products can be transported by it; 2. Large conveying capacity; 3. The traction chain has high strength and can be used for long-distance transportation; 4. The layout of transmission lines is flexible. Compared with the mesh belt conveyor, the chain plate conveyor can be transported under the condition of larger inclination angle and smaller bending radius, so the layout is more flexible. The inclination angle of chain plate conveyor can reach 30 ° - 35 °, and the bending radius is generally about 5-8m; 5. In the process of transportation, various processes such as classification, drying, cooling or assembly can be carried out; 6. Stable and reliable operation; Classification 1. The structural types of chain plate conveyor are diverse. Chain conveyor can be generally classified as follows: 2. According to the installation form of conveyor, it can be divided into fixed type and mobile type; 3. According to the layout of the conveyor, it can be divided into horizontal type, horizontal inclined type, inclined horizontal type, horizontal inclined horizontal type, etc; 4. According to the structural type of traction components, they can be divided into sleeve roller chain, stamping chain, casting chain, ring chain and detachable chain; 5. According to the number of traction chains, they can be divided into single chain type and double chain type; 6. According to the structural type of the bottom plate, it can be divided into scale plate (wave type with retaining edge, wave type without retaining edge, deep type with retaining edge, etc.) and flat plate (flat type with retaining edge and flat type without retaining edge, etc.); 7. According to the operation characteristics of the conveyor, it can be divided into continuous type and pulsation type; 8. According to the driving mode, it can be divided into electric mechanical driving type and hydraulic driving type. characteristic. Small floor area and flexible; *The direction is changeable, and the conveying direction can be changed flexibly, up to 180 degrees; *S-type roller conveyor, each unit is composed of 8 rollers. Each unit can be used independently or connected with multiple units, which is convenient for installation; *The S-type roller conveyor can expand and retract freely, and the ratio of the longest and shortest state of a unit can reach 3 times; *S-type roller conveyor can flexibly change the conveying direction, which can be greater than 180 degrees at the maximum. Roller conveyor is applicable to the transportation of various boxes, bags, pallets and other pieces of goods. Bulk materials, small items or irregular items need to be transported on pallets or turnover boxes. It can transport single heavy materials or bear large impact load. Structural form: according to the driving mode, it can be divided into power drum line and unpowered drum line, and according to the layout form, it can be divided into horizontal conveying drum line, inclined conveying drum line and turning drum line. It can also be specially designed according to customer requirements to meet the requirements of various customers. The inner width of standard gauge roller line is 200, 300, 400, 500, 1200mm, etc. Other special specifications can also be adopted according to customer requirements. The standard turning inner radius of the turning drum line is 600, 900, 1200mm, etc. other special specifications can also be adopted according to customer requirements. The drum diameters used for the straight section drum are 38, 50, 60, 76, 89mm, etc. characteristic 1. The conveying surface of the chain plate conveyor is flat and smooth, the friction is small, and the transition of materials between the conveying lines is stable. It can transport all kinds of glass bottles, PET bottles, cans and other materials, as well as all kinds of bags; 2. The chain plate has a wide variety of materials and specifications such as stainless steel and engineering plastics, which can be selected according to the conveying materials and process requirements, and can meet the different needs of all walks of life; 3. The frame material is divided into aluminum profile, ordinary carbon steel and stainless steel. 4. Large conveying capacity and can carry large loads, such as electric vehicles, motorcycles, generators and other industries; Plate conveyor production chain plate conveyor picture manufacturer 5. The conveying speed is accurate and stable, and can be transported synchronously; Plate conveyor production chain plate conveyor picture manufacturer chain plate conveyor, assembly chain plate conveyor 6. Generally, the chain plate conveyor can be directly washed with water or soaked in water. The equipment is clean and convenient, and can meet the hygienic requirements of the food and beverage industry; For cosmetics and washing products, make the conveyor chain plate always run in the guide rail. Pay attention not to damage the belt edge by the rope. The structure of the equipment is simple 7. Flexible equipment layout. Horizontal, inclined and turning conveying can be completed on one conveying line; 8. The equipment has simple structure and convenient maintenance. The selection method can select the chain plate with corresponding material and width as required. 1. Select the plate conveyor according to the conveying product - flat chain, and produce the chain plate conveyor picture, manufacturer and chain plate line manufacturer 2. Different forms of flat chain are selected to realize various functions such as plane conveying, plane turning, lifting and lowering. When using the crane to carry the chain plate conveyor, the requirements for single row conveying of cleaning and other equipment. 3. The motor can be set under or above the rack as required. Thickened iron plate conveyor reduces internal loss, resulting in storage capacity, transportation capacity requirements, etc 4. Variable frequency speed regulation or stepless speed reduction motor can be selected for speed regulation.

選購304stainlesssteelchainplate質保一年來黑龍江省找浩宇輸送機械制造廠(黑龍江省分公司),我們是廠家直銷,產品型號齊全,確保您購買的每一件產品都符合高標準的質量要求,選擇我們就是選擇品質與服務的雙重保障。聯系人:許經理,地址:[經濟開發區泰山路南首路西]。