電工鋼硅鋼片:比總損耗(鐵損) specific total loss (iron loss)比總損耗是在磁極化波形保持正弦,其峰值和頻率為特定值時,單位質量材料所消耗的總功率,比總損耗用符號 P(Jm/f)表示,單位為 W/kg。例:P1.5/50表示在 磁極化強度為 1.5T、遼寧營口當?shù)仡l率為 50Hz 時的比總損耗。3.2 磁極化強度 magnetic polarizationQ/BQB 480-20212磁極化強度是指試樣受交變磁化時,特定磁場強度峰值的磁極化強度峰值,其符號為J(H),單位為 T(特斯拉)。例:J5000表示對應于磁場強度峰值為 5000A/m 下的磁極化強度峰值。4 分類本文件的材料的等級是根據(jù)磁極化強度在1.5T、遼寧營口當?shù)仡l率在50Hz下的 比總損耗名義值P1.5/50(W/kg)、遼寧營口當?shù)夭牧瞎Q厚度進行牌號分類,并按產品特性細分為普通型、遼寧營口當?shù)貞ν嘶鹦秃托腿悺?/div>

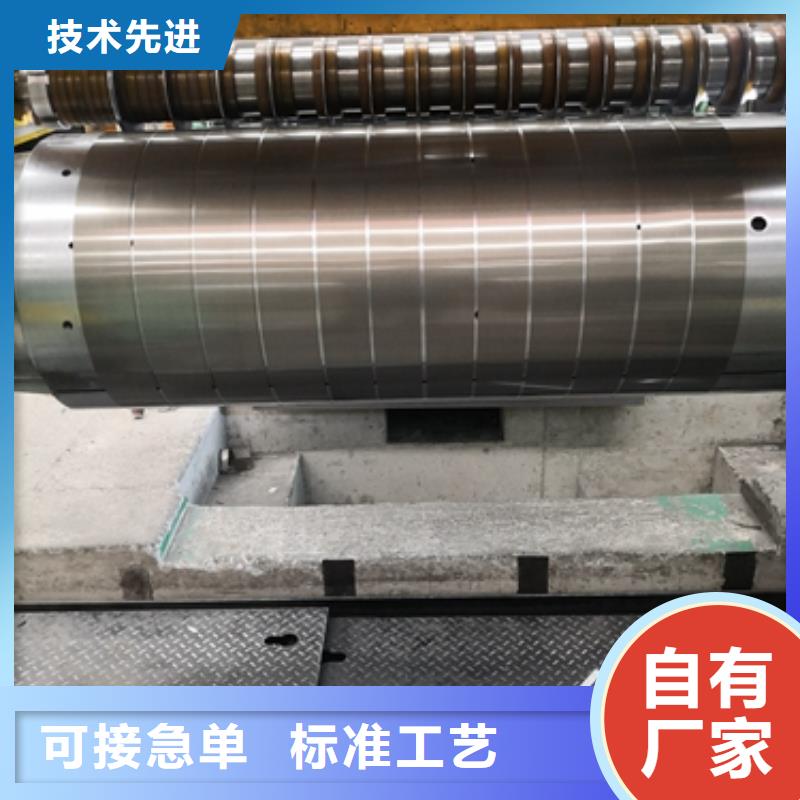

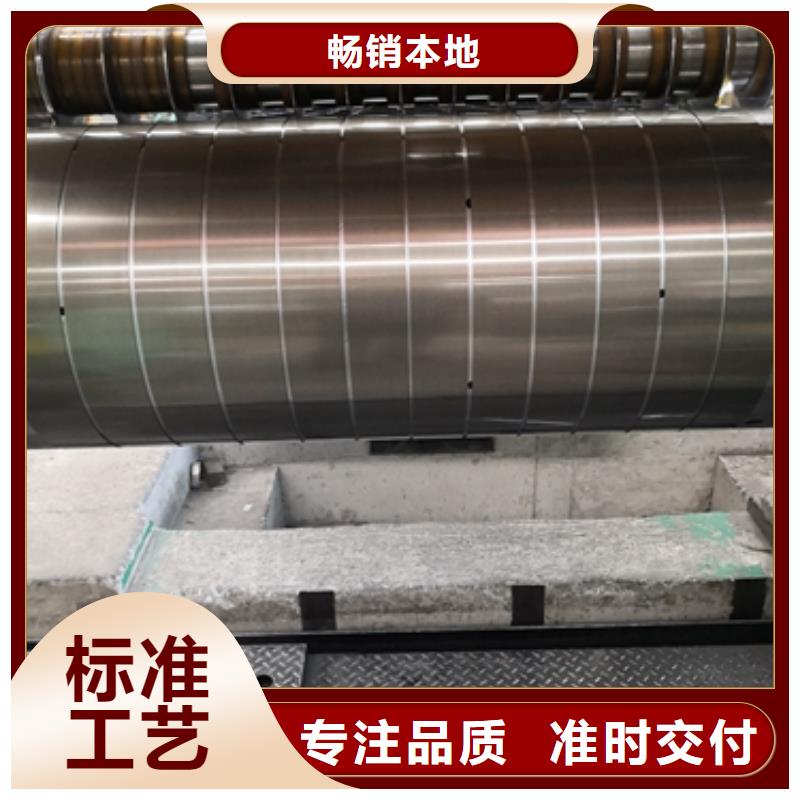

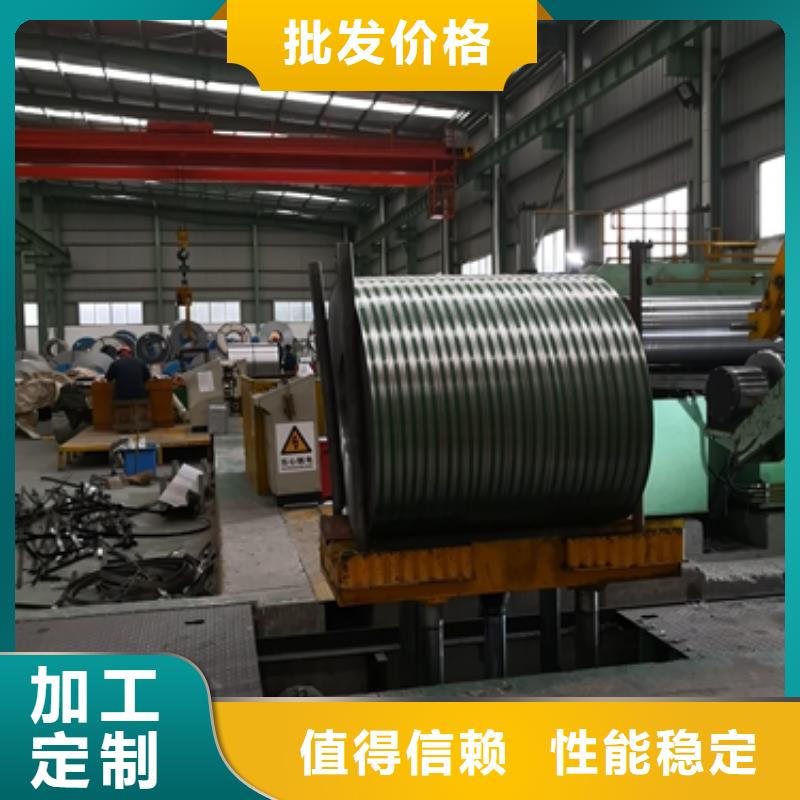

鹿程國際貿易(營口市分公司)專注于【新能源硅鋼】設計研發(fā)、生產制造以及銷售,公司一直秉承著:用心鑄就品質,誠信決定未來,服務即是生命的經營理念立足市場。不斷發(fā)展,不斷創(chuàng)新。公司具有先進設計研發(fā)技術,先進的設備,還有一批高素質的技術人員以及獨有的經營理念不斷突破創(chuàng)新與時俱進,打造行業(yè)高標準。 公司在寶山區(qū)蕰川公路777號寶鋼廠區(qū)607-609室設立了工廠,營銷網絡遍及全國,能夠為客戶提供快速**的服務。目前,公司產品的暢銷中國,并出口到歐美、中東等地區(qū)。鹿程國際貿易(營口市分公司)力助客戶商業(yè)成功,歡迎洽談。

電工鋼硅鋼片寶鋼可以為客戶提供性能數(shù)據(jù)原始曲線和其他形式的數(shù)據(jù)。GB20052-2020新能源效率一級產品S15-M-200/10、遼寧營口附近S15-M-400/10變壓器成功投產用高等級GO電工鋼B18R055制造,B20R060,其空載損耗和負載損耗均滿足新的1級變壓器的要求。寶鋼高級晶粒取向電工鋼B27R090成功應用于雙百萬變壓器的制造ODFPS-1000000/1000用于超高壓交流輸電項目包括空載損耗在內的所有變壓器特性,空載電流和噪聲符合設計要求。寶鋼優(yōu)質晶粒取向硅鋼B23R075已成功應用于轉爐生產昌吉-古泉±1100kV特高壓直流輸電變壓器 電網項目。空載損耗、遼寧營口附近空載電流和噪音變壓器的各項性能完全符合技術要求。 無機涂層,S/T2 涂層為磷酸鹽和二氧化硅為主的無機成分混合物。該涂層具有較高的耐熱性,在干的氮氣或者干的氮氫混合保護氣氛中可以承受 850℃應力退火。對絕緣油、遼寧營口附近清漆、遼寧營口附近機械油、遼寧營口附近制冷氣體等有高耐腐性。 無 Cr 環(huán)保涂層,H,涂層成分中不含 Cr 元素

電工鋼硅鋼片Electrical steel, also known as silicon steel sheet, is an indispensable metal material in the power, electronics, and military industries, and is also the largest functional material in production. It is mainly used as the iron core for various motors, generators, and transformers. Since it is a functional material, its performance testing also revolves around "function". These indicators are often mentioned in trade and processing processes, and a brief understanding can help everyone better carry out their work. The performance testing of electrical steel mainly includes the following aspects: magnetic inspection, stacking coefficient inspection, coating adhesion inspection, repeated bending inspection, size and shape surface inspection, and conventional mechanical property inspection. In addition to the types of products listed above, there are also some special purpose electrical steel plates, such as 0.15 and 0.20mm thick 3% Si cold-rolled non oriented silicon steel strips and 0.025, 0.05, and 0.1mm thick 3% Si cold-rolled oriented silicon steel strips, which are used as intermediate and intermediate grade High frequency motors and transformers, as well as pulse transformers, etc; 0.7mm thick 3% Si high-strength cold-rolled non oriented silicon steel plate for relays and power switches; High strength cold-rolled electrical steel plate for new high-speed motor rotors; Low carbon electrical steel hot-rolled thick and cold-rolled plates for magnetic shielding and high-energy accelerator electromagnets such as medical magnetic resonance tomography scanners; 4.5% to 6.5% Si high silicon steel plates for high-frequency motors, transformers, and magnetic shielding.

Generally, motors, transformers, and other electrical components are required to have high efficiency, low power consumption, small size, and light weight. Electrical steel plates are usually guaranteed to have magnetic properties based on core loss and magnetic induction strength. Magnetic induction strength is the number of magnetic lines passing through a unit cross-sectional area of the iron core, also known as magnetic flux density. It represents the material‘s magnetization ability, measured in T. The magnetic induction strength of electrical steel plates is high, and the excitation current (also known as no-load current) of the iron core is reduced. Copper and iron losses are also reduced, which can save electrical energy. When the power of the motor and transformer remains constant, the magnetic induction intensity is high, and the design Bm can be increased. The cross-sectional area of the iron core can be reduced, which reduces the volume and weight of the iron core, and saves the amount of electrical steel plates, wires, insulation materials, and structural materials used. This can reduce the total loss and manufacturing cost of the motor and transformer, and is beneficial for the manufacturing, installation, and transportation of large transformers and motors. The main requirements for the performance of silicon steel are:

1. Low iron loss is the most important indicator of the quality of silicon steel sheets. Various countries classify grades based on iron loss values, with the lower the iron loss, the higher the grade.

2. Under strong magnetic fields, the magnetic induction intensity (magnetic induction) is high, which reduces the volume and weight of the iron core of the motor and transformer, saving silicon steel sheets, copper wires, and insulation materials.

3. The surface is smooth, flat, and the thickness is uniform, which can improve the filling coefficient of the iron core.

4. Good lamination performance is more important for manufacturing micro and small electric motors.

5. The adhesion and weldability of the surface insulation film are good, which can prevent corrosion and improve the punching performan

在遼寧省營口市采購0.1mm進口極薄硅鋼 GT080銷售請認準鹿程國際貿易(營口市分公司),品質保證讓您買得放心,用得安心,廠家直銷,減少中間環(huán)節(jié),讓您購買到更加實惠、更加可靠的產品。(聯(lián)系人:鹿丙偉-【13764370568】)。